Service

Oil Cleanliness is the key criteria of hydraulic systems health. All hydraulic system needs to be periodically tested for oil cleanliness level and the level need to be maintained as specified by OEM. This is very important for proper operation and long service life of a hydraulic system. Contaminated fluid causes most hydraulic system failures. silt contamination particles are too small to see can still wreck pumps, cause valves to stick, and erode cylinder bores. Without preventive measures and fluid conditioning, their negative effects can escalate to the point of system/component failure.

Fluidforce Filtration solutions provides reliable contamination monitoring and control systems for hydraulic systems installed on all industrial, marine and offshore sectors. We carefully monitor, maintain and ensure the systems cleanliness standards, so it operates with maximum efficiency and increased lifespan.

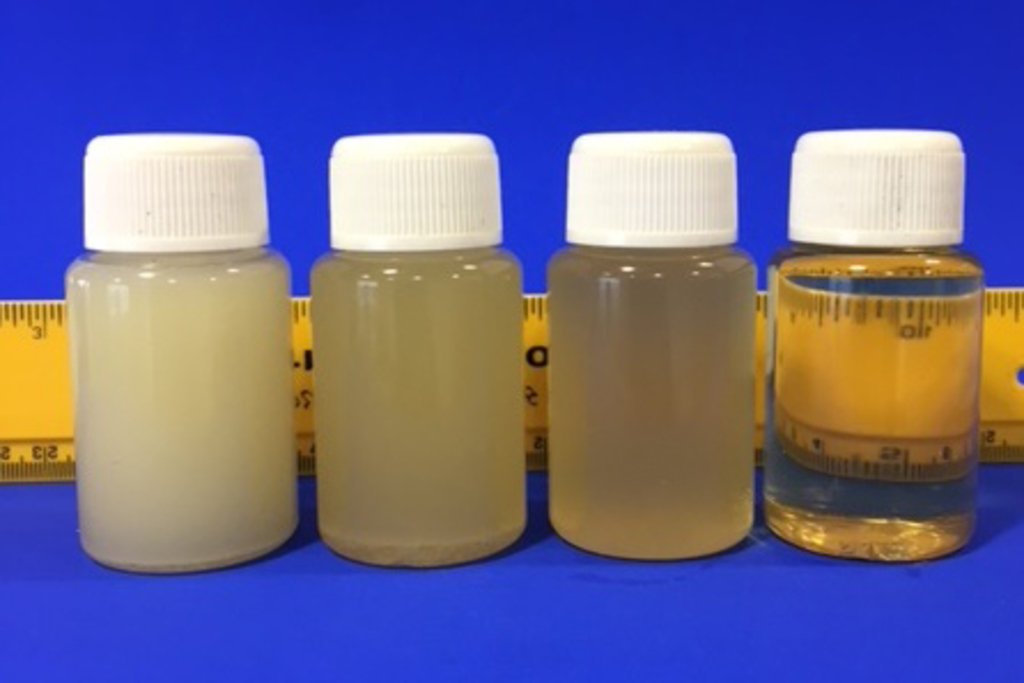

Our portable equipments fleet were developed to fit in the narrow spaces of offshore and marine installations, consists of fluid filtration trolleys and contamination testing units and patch test kits compatible to handle various fluid types, suitable to carry out contamination monitoring and testing onsite either online or offline. We conduct analysis as per ISO4406 or NAS 1638 standard.